The structure/frame

All conservatories are made from 6061 T6 aluminium, which perfectly balances lightness and robustness; this material is also used in aeronautics and is highly corrosion resistant.

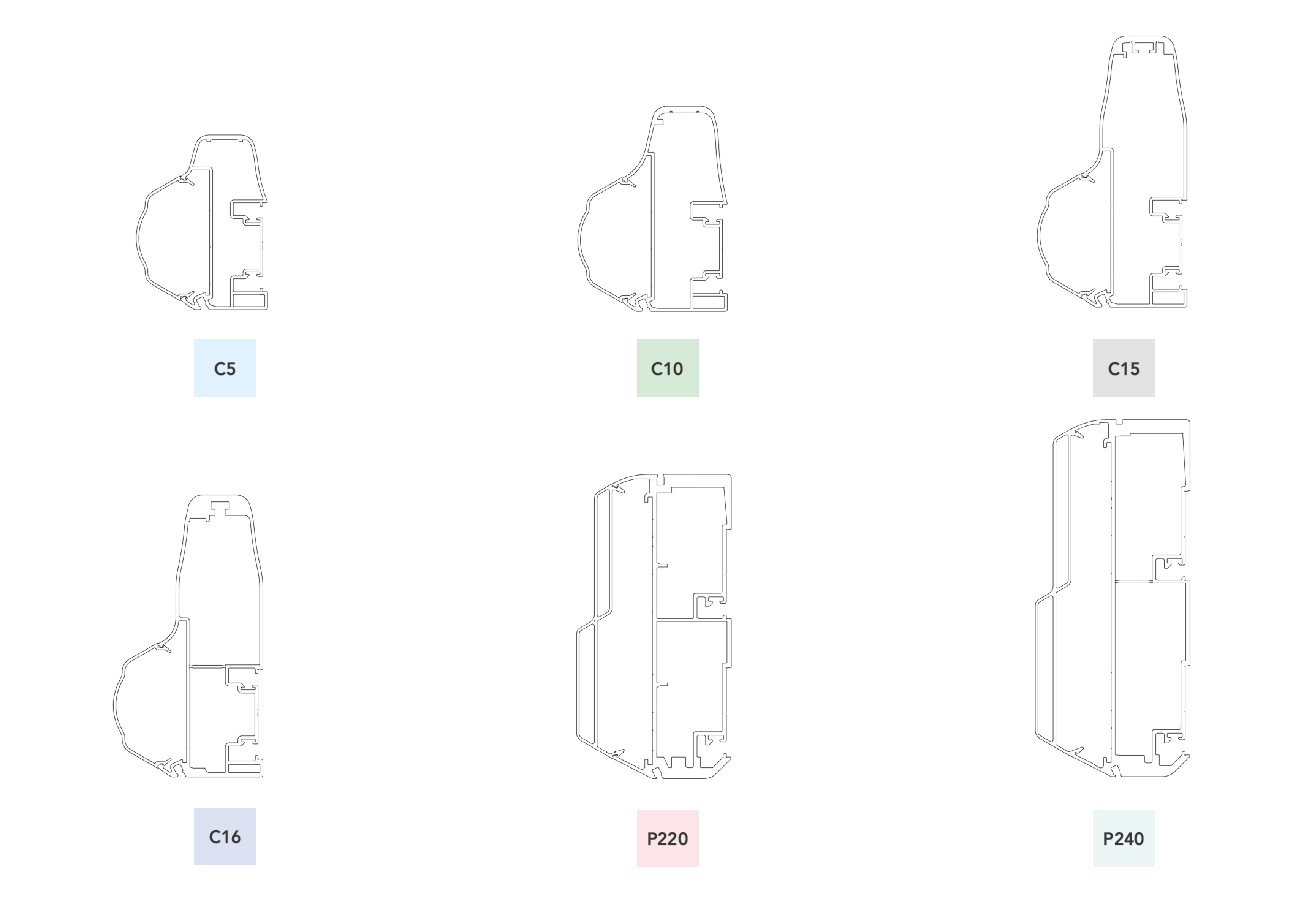

Sections

The sections of the frame are unique and specially designed by our own design office. They are extruded through a die by SAPA Aluminium, renowned for its reliability. Each part is treated against corrosion both inside and outside the structure. The sections are tested by an external design office (AIB Vincotte) for resistance to snow load. The kind of section is determined according to the size of the conservatory and the geographic area in which it will be installed.

Angle brackets

Angle brackets are used to connect the sections. These connectors are dimensioned to have a resistance greater than or equal to the frame itself.

Made from aluminium 7075, they are more resistant than steel, which means that the break point can be eliminated.

VISSERIE ET ACCESSOIRES

L’ensemble des éléments composant la visserie sont en acier inoxydable A2. Contrairement à certains fabricants, nous n’utilisons pas de visseries zinguées ou galvanisées qui s’oxydent avec le temps. L’acier inoxydable permet les éventuels démontages ou entretiens de l’abri même après de longues années.

Anchoring components and materials

A side attach tab is integrated on each element. Chemical anchors on the stainless steel case allows it to be secured in the ground (in a reinforced concrete stud produced by the client). Therefore it is enough to tighten the stainless steel and plastic spur via the opening provided for this purpose. The anchoring or disembedding time is approximately 10 minutes for an average conservatory of 5 components, which goes to show how easy the process is. Once the structure has been embedded by a side anchor, this element offers optimum stability in extreme winds and maximum reinforcement of the conservatory against snow load, unlike the longitudinal anchor.

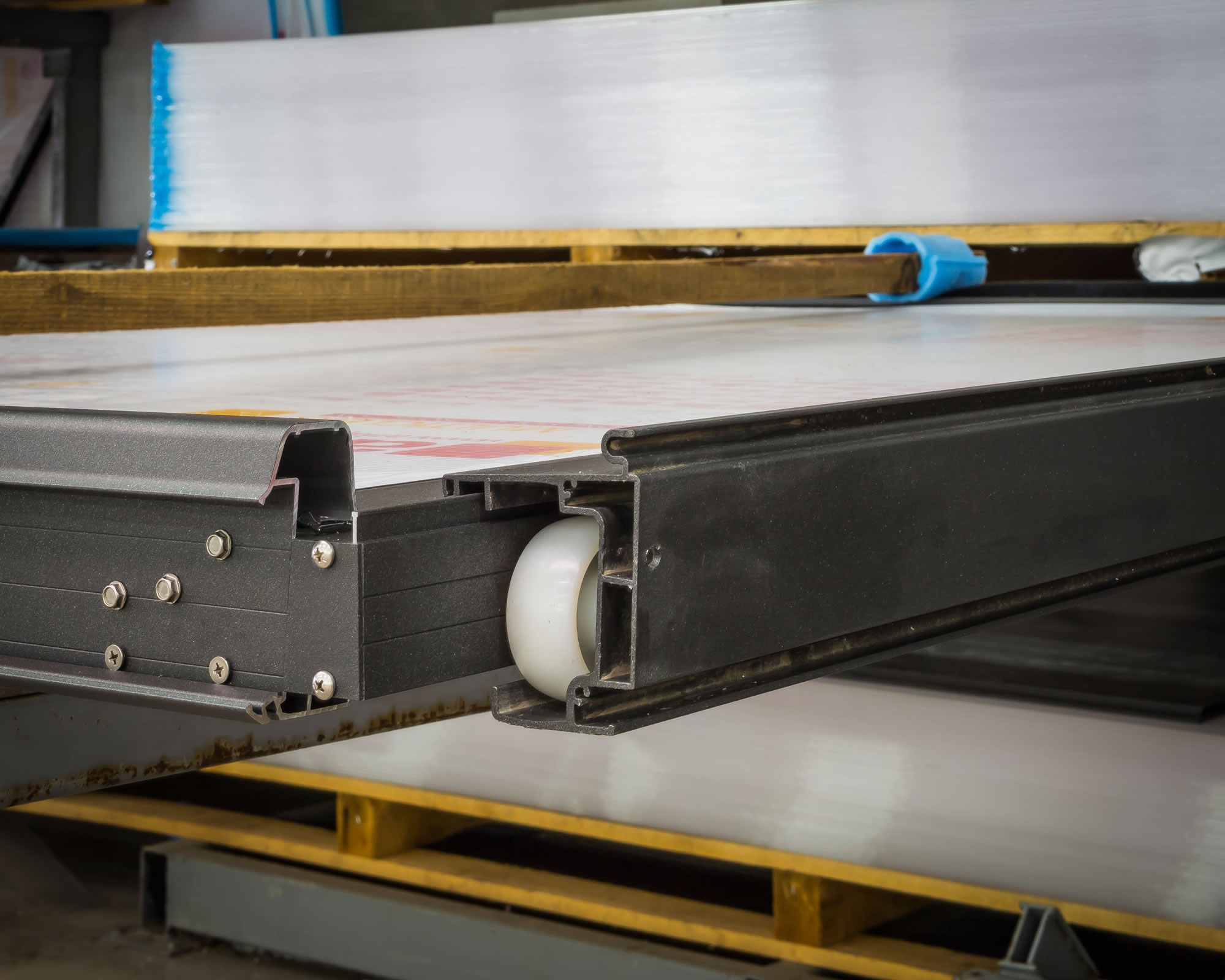

Lateral guide

All guide bushes are integrated into the structure and are fully concealed. Developed to customised specifications and patented by GRS, they do not need any oil. Optimum working order can only be guaranteed by their cleanliness.

Locks and handles

Accessories (lock, handles) are made from aluminium or stainless steel for the sake of quality and longevity.

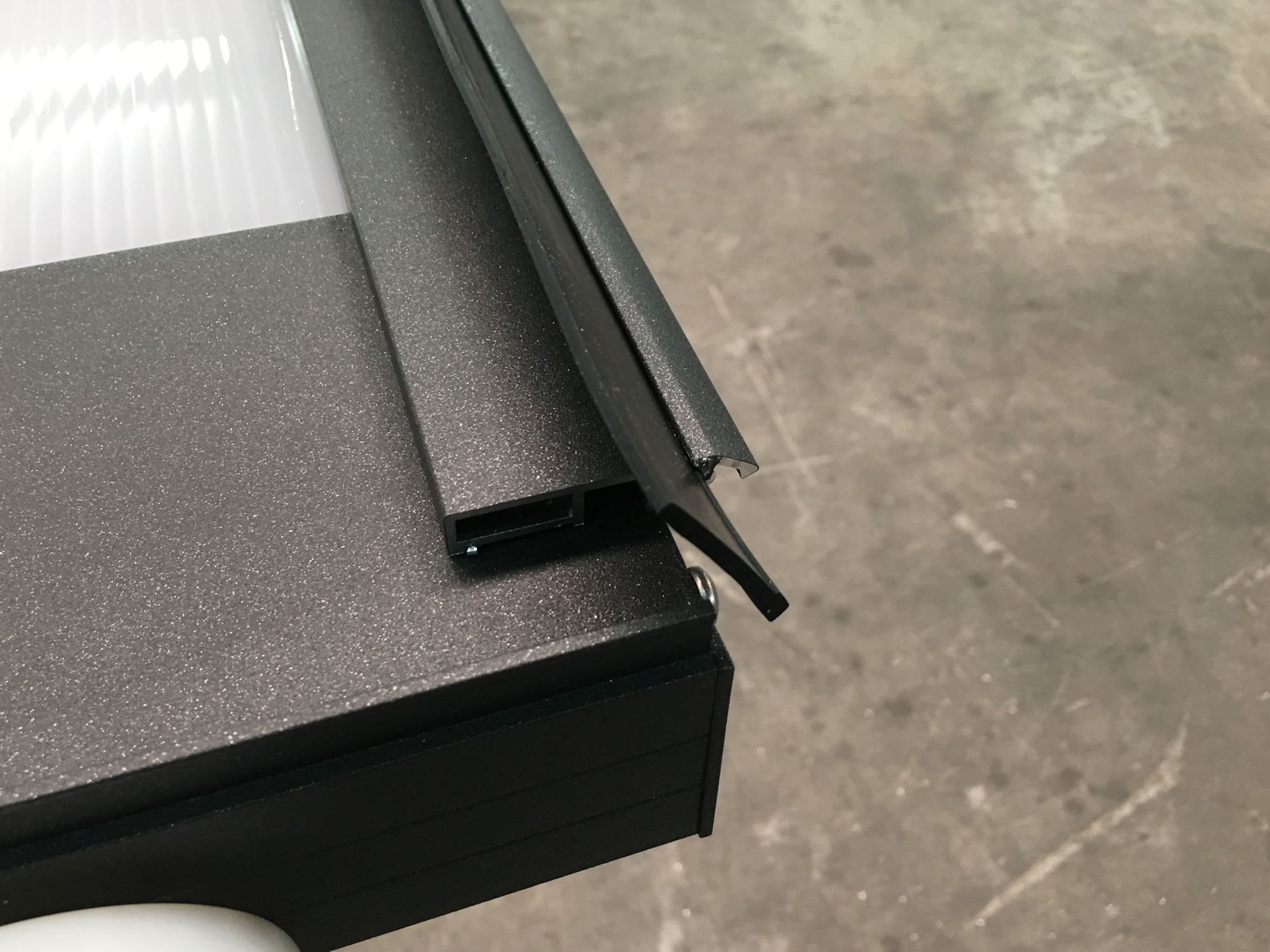

Sealing

The seal between the components is provided by rubber seals which guarantees greater water-tightness.

The inside of the conservatory is protected from draughts, thorns and dust.

Side glazing

Side glazing (assembly on glazing stop)

The roof

Of the Lexan brand, the roof sheet is unbreakable. Its thickness of 6 millimetres intrinsically tightens the alveoles by which it is constituted, which strengthens its resistance in relation to a sheet of 12 millimetres. It is translucent or of an opaline white colour. The UV treatment applied to the two faces takes into account the reverberation of the light, which prevents yellowing. The roof sheets are not screwed down but held in grooves and glued. At the ends of the sheets, a micro-perforated plate is placed to allow the plate to breathe in order to prevent interior condensation and prevent dust and insects from getting inside.

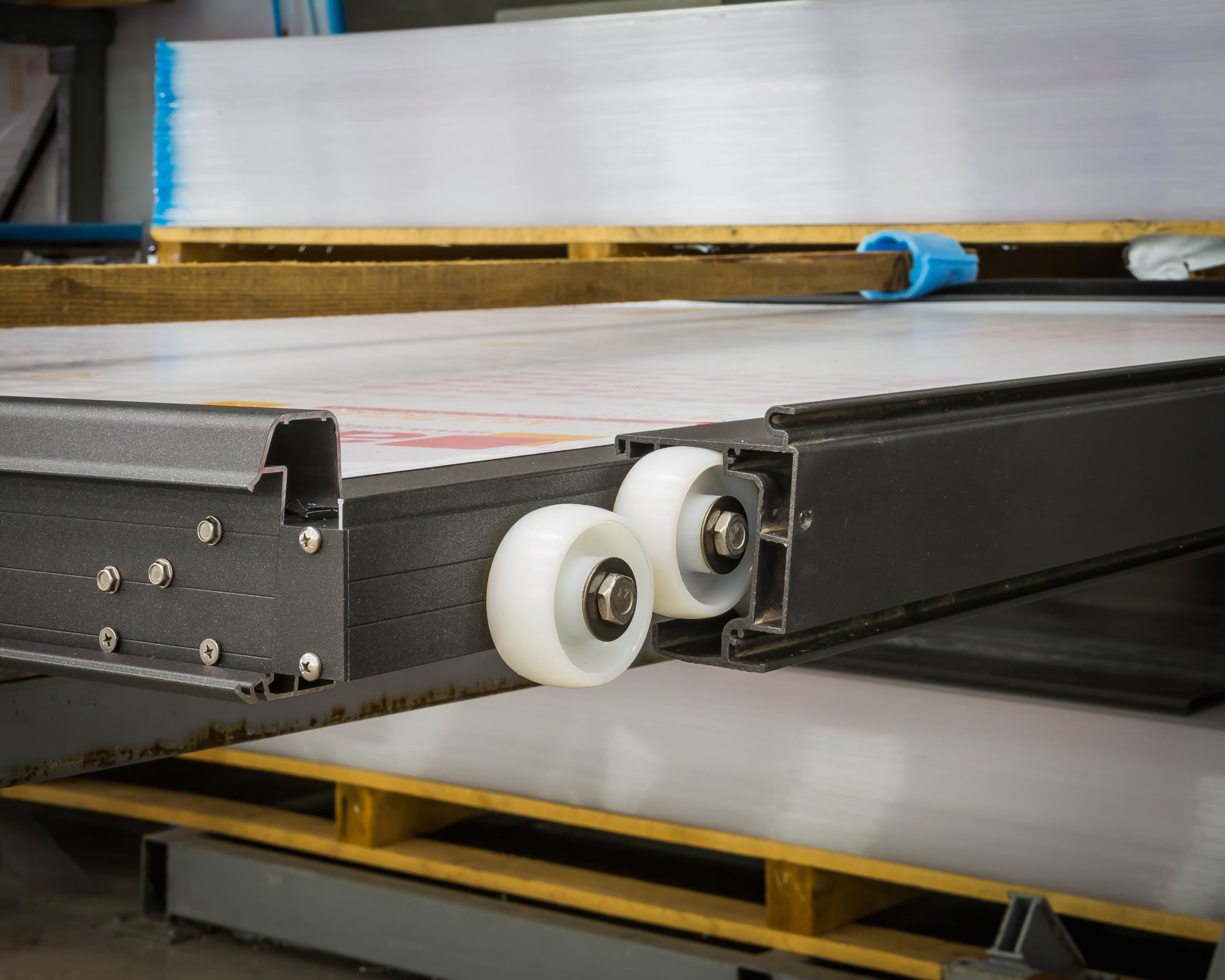

Wall guiding of elements

The elements are connected to each other by a system of guide rollers integrated in the structure. This system of rollers and spacers allows the telescopic structure to slide fully and smoothly.

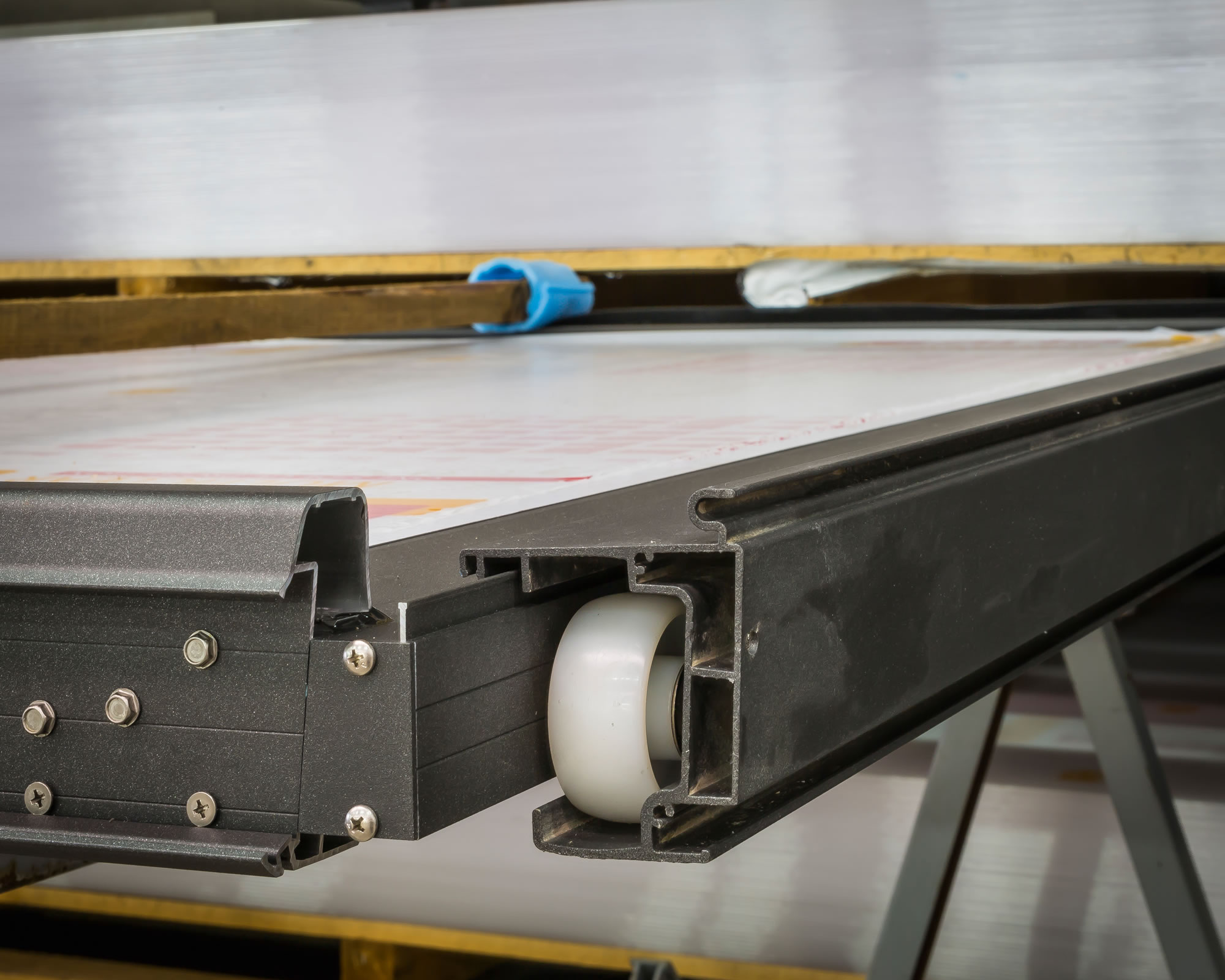

The ground roll

The rollers are finger-mark resistant polyamide monolithic wheels (surrounded by a blue rubber strip to absorb any impacts) mounted on stainless steel needle bearings which allow the conservatory to move very easily and protect against virtually all forms of wear and tear.